|

Maximum capacity

60 t

|

|

|

Maximum lifting height

14,5 m

|

|

|

Maximum lifting distance

11 m

|

Pick&carry electric mobile cranes

We have extended our range of machines with specially designed electric Pick & Carry mobile cranes for specialist lifting applications. They are compact and ideal for lifting, moving and machine installation in confined spaces and indoors.

What does Pick & Carry mean?

Pick & Carry = grab and move

Pick & Carry machines are hall or mobile cranes that can move around carrying the load they have lifted without being jacked. Their compact size makes them ideal for special lifting and moving applications indoors, allowing machines to be lifted from the transport vehicle and moved into position indoors in a single operation.

Electric hall crane

It is a precision, all-electric, zero-emission machine that combines the benefits of a forklift truck, a loader and a truck crane. Depending on the task, it can lift loads with a winch, fixed hook, hall top, or forklift adapter (to act as a forklift and a loader). Its main advantage is that it has rear-wheel steering, meaning it can turn on a dime and get into every nook and cranny.

If the quality of the ground is poor, we build a suitable route with our large steel plates. Using this quick fix we can also bridge over open or low load-bearing covered process tunnels. With our Pick & Carry machines we can work much quicker than with forklifts and heavy-duty roller skids.

ORMIG pick&carry electric mobile cranes

- These cranes can lift, move and transport loads of up to 60 tonnes gross

- With their compact size, they can access tight work areas without the need to knock down walls, even through narrow and/or low industrial doors

- Their manoeuvrability beats that of conventional truck cranes, allowing easy access to the work area between production lines

- They accelerate implementation, reduce timelines and provide a more cost-effective solution for our customers

- They are suitable for indoor, clean room and outdoor use. They can move and carry objects without any problems, even on uneven surfaces.

- With their hall tops, they can easily lift and move loads in low-ceilinged spaces.

- All of their functions can be controlled from outside the cab by radio remote control.

- With their forklift accessory, they can be used as 22-tonne rated forklifts or as loaders, something that other companies in Hungary can’t offer with ease

- Their turning radius is almost the same as that of a similarly-sized forklift

Request our offer for specialized machine moving

Ormig 55/60 iE

It is a precision, all-electric, zero-emission machine that combines the benefits of a forklift truck, a loader and a truck crane. Depending on the task, it can lift loads with a winch, fixed hook, hall top, or forklift adapter (to act as a forklift and a loader). Its main advantage is that it has rear-wheel steering, meaning it can turn on a dime and get into every nook and cranny.

If the quality of the ground is poor, we build a suitable route with our large steel plates. Using this quick fix we can also bridge over open or low load-bearing covered process tunnels. With our Pick & Carry machines we can work much quicker than with forklifts and heavy-duty roller skids.

|

Maximum capacity

16 t

|

|

|

Maximum lifting height

12 m

|

|

|

Maximum lifting distance

10,45 m

|

Ormig 16tmE

Our hall cranes are equipped with non-marking white wheels, and being electric powered, they operate without harmful emissions, allowing them to be used without any problem in clean rooms, and chemical and food environments. These cranes can lift, move and transport loads of up to 16 tonnes gross. With their forklift accessory, they can be used as forklifts of 6 tonnes rated capacity,

Your safety is important to us. Our machines can be operated by radio remote control, allowing the operator to move around freely. This feature reduces the risk of dangerous situations arising in the work area, thus promoting safe working conditions. As a consequence of the radio remote control, the headcount of the banksmen can be reduced by 50%, resulting in a cost efficient solution for our clients. We carry out lifting technology and machine installation services in confined or clean spaces.

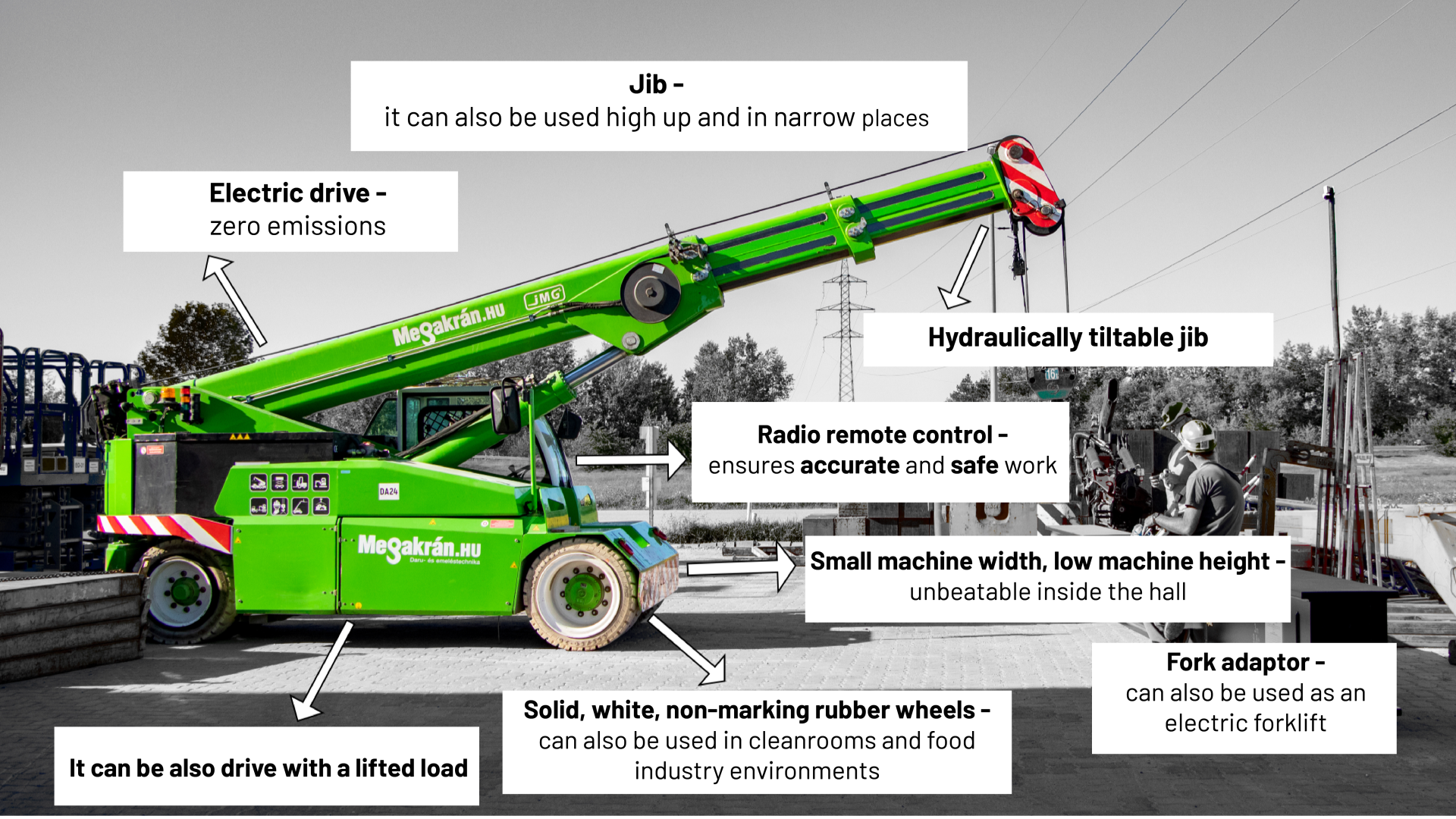

JMG pick&carry electric mobile cranes

- Combine the benefits of forklifts, stackers and truck-mounted cranes

- They can turn 360 degrees around the front axle and 180 degrees around the rear axle, making it easy to negotiate sharp bends between production lines without disrupting production

- Dead space in the cab can be a problem when lifting and moving in confined spaces, but the radio remote control allows safer and more accurate work

- They have a hall top adapter, making them ideal for working at height and in confined spaces

- Their white, non-marking wheels are perfect for any floor

- With their forklift accessory, they can be used as forklifts

- They are also an excellent solution for changing tools on machine tools

Request our offer for specialized machine moving

|

Maximum capacity

16 t

|

|

|

Maximum lifting height

12 m

|

|

|

Maximum lifting distance

10,7 m

|

JMG MC160

JMG electric cranes with their compact size, they can access tight work areas without the need to knock down walls, even through narrow and/or low industrial doors. Their manoeuvrability beats that of conventional truck cranes, allowing easy access to the work area between production lines. Dead space in the cab can be a problem when lifting and moving in confined spaces, but the radio remote control allows safer and more accurate work.The maximum lifting capacity of our JMG MC160 hall crane is 16 tons, while assembled with fork has maximum capacity is 8 tones

|

Maximum capacity

9 t

|

|

|

Maximum lifting height

8 m

|

|

|

Maximum lifting distance

5,5 m

|

JMG MC90

JMG electric cranes with their compact size, they can access tight work areas without the need to knock down walls, even through narrow and/or low industrial doors. Their manoeuvrability beats that of conventional truck cranes, allowing easy access to the work area between production lines. Dead space in the cab can be a problem when lifting and moving in confined spaces, but the radio remote control allows safer and more accurate work. Our JMG MC90 type of hall crane has a maximum lifting capacity of 9 tons while assembled with fork has 4 tons lifting capacity.The width of the machine is only 1.5 meters, making it perfectly suitable for moving and installing machines in extremely narrow spaces.

Our solutions

Our solutions

Our solutions

Our solutions

Our solutions

Certificates

Do you have any questions?

Do not hesitate to contact us

Follow us